Dosage and Coloring

Colortech

Our machines are designed for precise dosing of quantities of additives, also in very small percentages. The mechanics are the same for the three models that compose the range; the difference is the control that operates them:

- COLORTECH STEP, universal dosing machine, suitable for all types of processes.

- TEST COLORTECH conceived mainly for injection moulding, varies the speed of rotation of the screw automatically, according to the charging time of the press to ensure the required percentage.

- COLORTECH EXT particularly suitable for extrusion and blow moulding, according to the screw speed of the extruder (received through a signal) the machine automatically varies its speed and always dispenses the required percentage.

Essential when the requested dosing of additive is minimum, that is when the percentage lowers under 1 %, or when the materials to be dozed and mixed are more than two, ex. virgin + ground and additive. It is applied between the hopper and the plasticization chamber, with the dozer that pours the additive directly in the mixing drum.

- Construction in steel AISI 304

- Arm in stainless steel with anti-wear treatment 70 rpm.

- Security Micro on the closing lid

- Gear motor 400V. 50/60 Hz Kw.0,25

- Electrical control panel that can be interfaced with the dozer

e

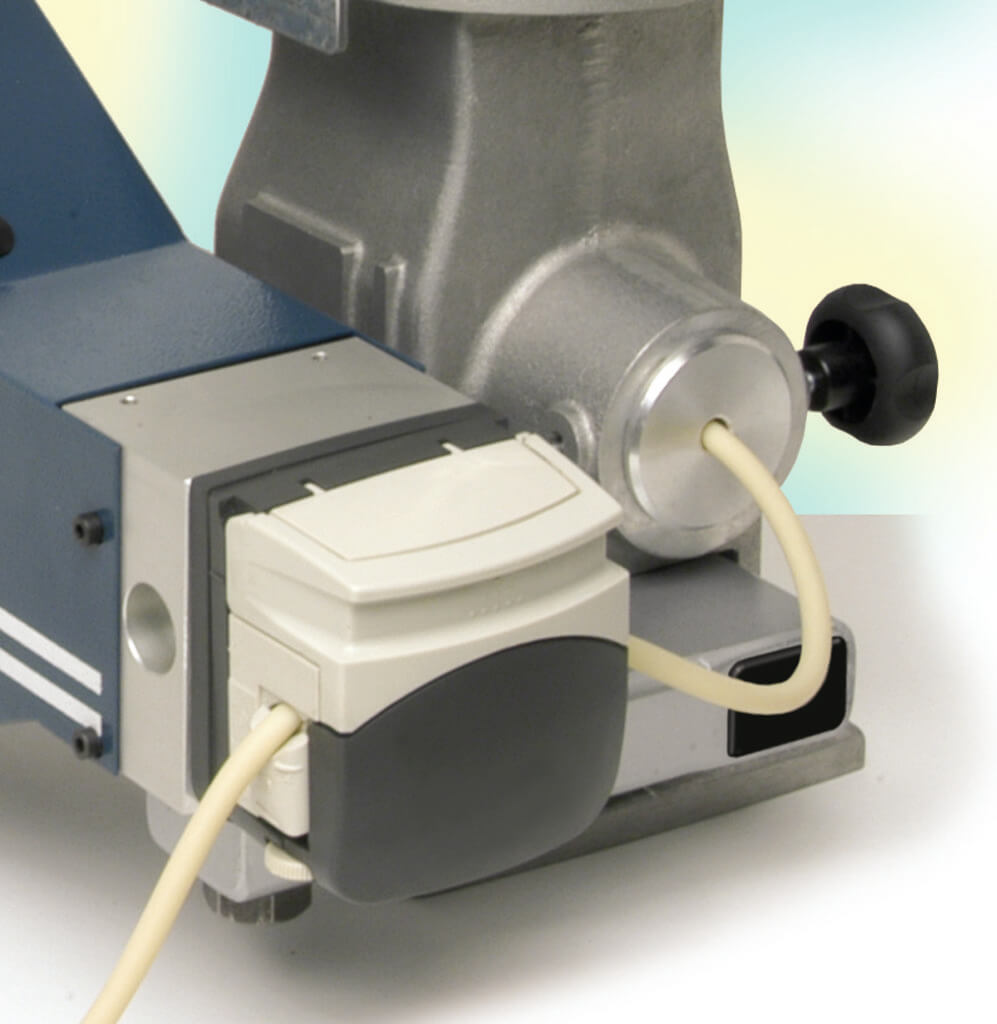

Keeping the same mechanics and the same controls and replacing the screw/ barrel unit with a peristaltic pump, the Colortech changes in to a perfect dosing unit for high viscosity liquids and additives, while maintaining the high precision characteristics.

Colortech API

For the determination of large quantities of granules, even if not re-ground with the same accuracy, of models for Masterbach, the COLORTECH AP has a powerful motor that is controlled by a vector inverter combining power and precision.

The version with feeding screw has been designed to dose PET flakes, light materials and powders.

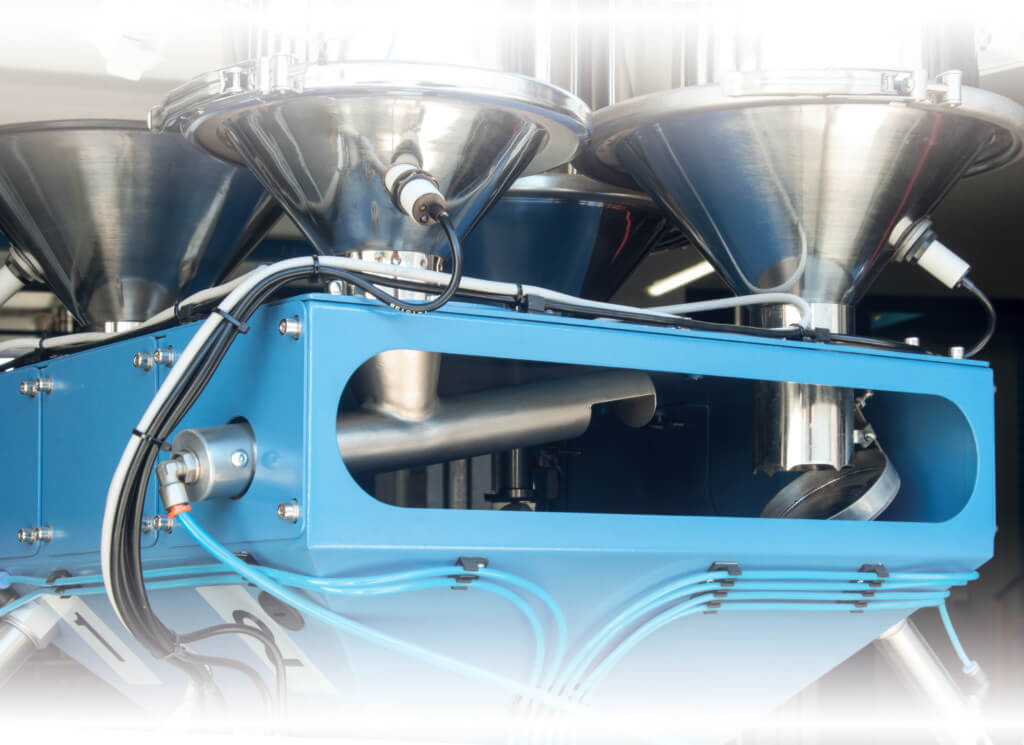

GDM

GRAVIMETRIC FEEDING AND BATCHING THROUGH INTEGRATED PRODUCTION SUPERVISION

Gravimetric dosing particularly suitable for injection moulding, blow moulding machines and extruders, filling and packaging machines for granulated and powdery materials. The solid steel machine frame and the particular software allow its installation even on machines with constant and controlled vibration. The different types of construction allow the combination of 2 to 6 components, differently dosed in small amounts with normal dosing screw.

The programming and management of the recipes is simple and easy: on the control touch screen each function is indicated by a symbol that represents the part you are programming and in the case of any malfunctioning, each part is represented on the screen.

GWM

GWM is the result of experience matured in more than 15 years of installations around the world on extruders. GWM is not a simple combination of WM CONTROL and GDM but it expands both their productive characteristics and modularity.

Main features:

– All-in-one control (gravimetric and WM) from a single location.

– flow control capacity up to 1.200kg/h;

– mixing components capacity up to 800kg/h;

– integrated colour touch screen control;

– one single control can handle five heads, a PC can handle 12;

– quick disassembly for cleaning or material change, thanks to the fully removable

dosing groups and large doors;

– Opportunity to network connection for Remote/automated management functionality.

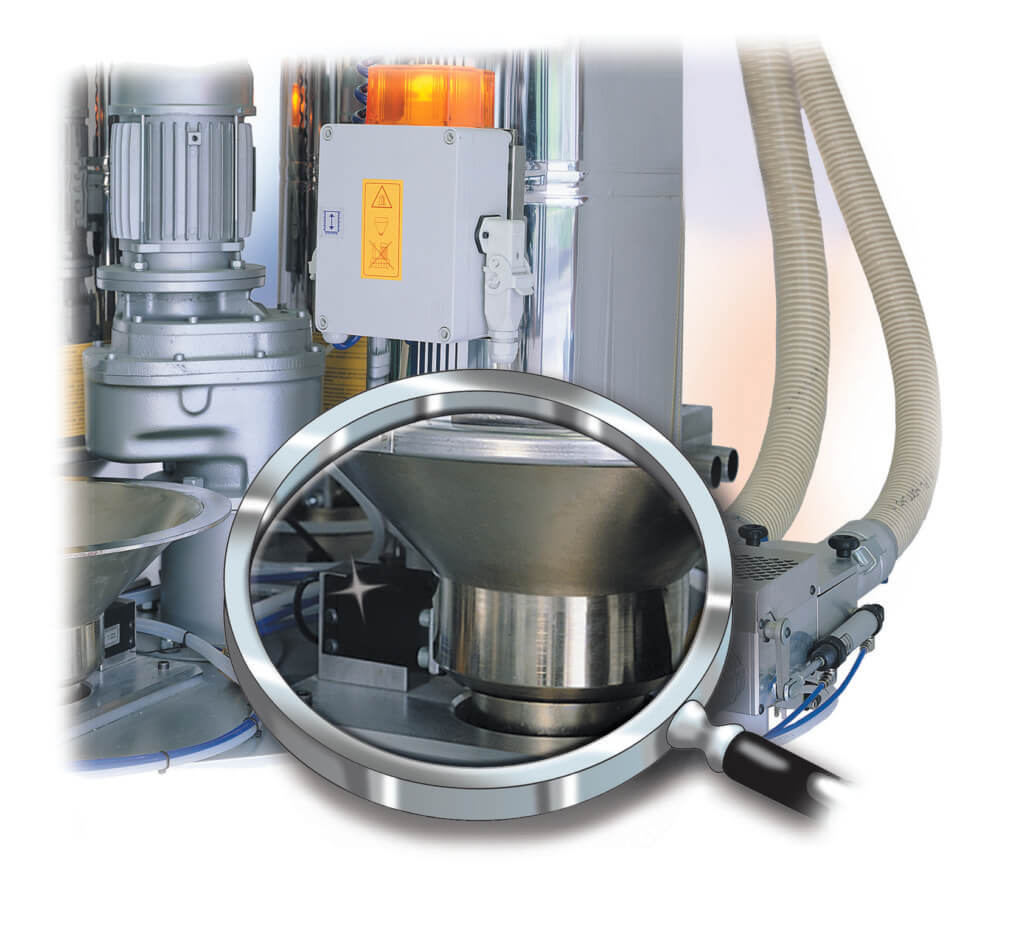

ADG

The precise gravimetric dosing unit (ADG) with an accuracy of 0.6 Kgs/1.000 Kg dosed is suitable for the use on extruders and

co-extruders where precision and consistency of mixing is required. The unit is suitable for dosage from 100 to 2.000 Kg/hour and from 2 to 12 materials/additives.

The system is based on the instalment of a common feeder on a loading cell. Every cyclone is equipped for loading two materials. The loading cell weighs the first material entering the yclone; when it reaches the required weight, it activates a valve that switches for the loading of the second material etc.. Once the total weight is reached the whole material falls into the mixer and is mixed for at least 7 minutes.

WM Control

Automatic determination of the average thickness of each piece and constant maintenance during all the production. The system is connected to the speed control of the extruder rotation and to the speed control of the pull off. The GENIUS control is able to manage up to 3 Co-extrusions. The pull off controls and the Co-extruders controls, are all grouped in the same panel, while the speed synchronization of screw’s rotation and the pull off will facilitate the speed up and the start up, reducing the timing and the waste parts. The resistant structure built in stainless steel (INOX AISI 304) brings support to the extrusion hopper or to the hopper loader. If any of the extrusions is fed by more materials, the dosing system can be mounted directly onto the extrusion machine.